The Power of Air Density

The Power of Air Density

Air density is one of the most overlooked factors in making power. Engine displacement, big turbos, large head ports and high lift cams only maximize air flow when the volume of air is at its highest. We at Fine Line Imports have put together some useful information regarding the effect of air density on engine power, gained through our own research and test runs performed in our dyno room over the past 3 years. All data shown in this article was logged at the time of the actual dyno run.

Temperature, humidity and altitude are major factors that need to be addressed when trying to achieve maximum engine power. Fuel quality, tuning and the level of volumetric efficiency (“VE”) of the engine also play important roles. VE is an important factor that will not be discussed in this article. This article will only address the topic of air density.

The number one factor that decreases air density is heat. A direct effect of heat through the intake manifold (metal) is heat soak. Heat soak occurs when the engine’s air charge stops and the metal surrounding the intake of the engine, specifically the intake manifold, absorbs this energy,. Once the intake manifold gets warm it is hard to cool it down, hence the reason intake air temperature is so important. The entry of air into the engine is controlled by the throttle body, which is located in the middle of the intake manifold. The factory intake air temperature (“IAT”) sensor on any U.S. turbocharged Subaru is located on the intake tube near the air box with the mass air flow (“MAF”) sensor. This is a very poor placement and representation of actual IAT. You can have a difference of anywhere from15 and 95 degrees between the intake manifold and air intake tube!

Most modern turbo charged cars come with an intercooler, which helps cool the air charge before it enters the engine. Remember the colder the air, the denser it is. The hotter the air, the less dense it is. Humidity is another factor that works in conjunction with temperature to affect air density. The more humid the air, the more dense it is and vice versa.

The two main styles of intercoolers are front mount intercoolers (“FMICs”), which mount in front of the radiator, and top mount intercoolers (“TMICs”), which mount on top of the engine. Both have good and bad features.

FMIC

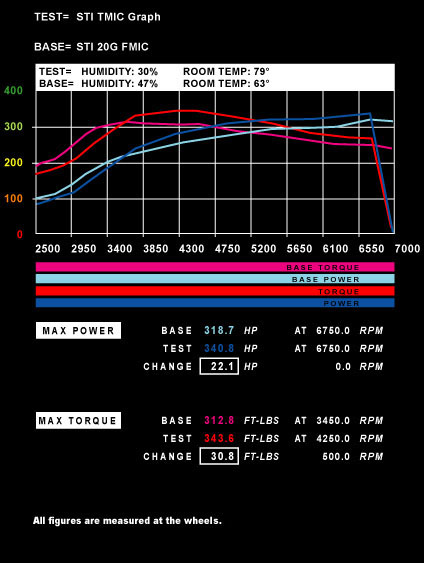

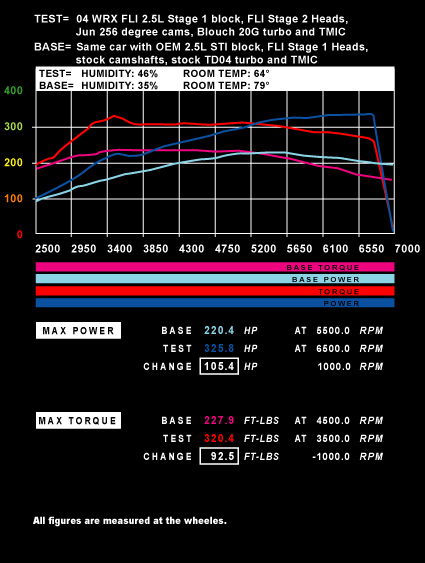

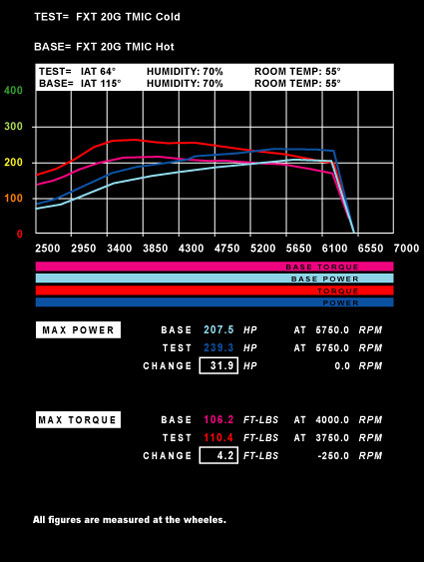

The major benefit of a FMIC, is the cooler temperature of air charge due to the FMIC’s location in front of the car’s radiator. The disadvantage of a FMIC is the extra lag time due to the longer length of intake piping that must be filled. If you compare a well-tuned FMIC map to a TMIC map on the same car with the same modifications using the same fuel, you will usually see higher horsepower and torque levels at higher rpms with the FMIC. This is because you can run more boost at higher rpms due to the cooler intake air charge. Keep in mind that if you do not have high quality fuel, a well-serviced engine and a turbo that can support the volume of air needed you will not make the extra power you are looking for. If you want response, then you might benefit from using a TMIC instead. As you can see from dyno graphs immediately below, the TMIC set up produces much more response in power but drops off near the top of the power band. If you are looking for a car that pulls hard at the higher rpm bands but has a little bit more lag, then the FMIC is for you. These dyno graphs show before and after on the same cars.

TMIC

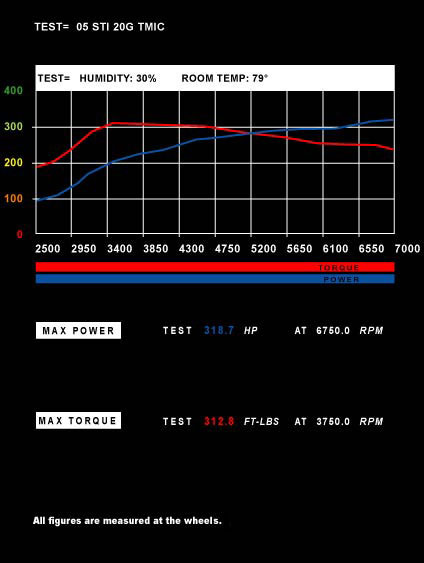

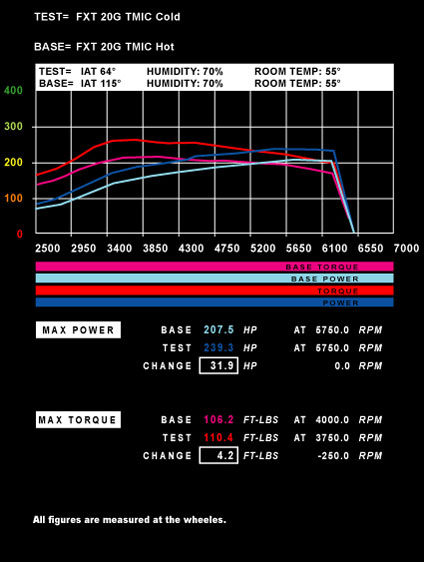

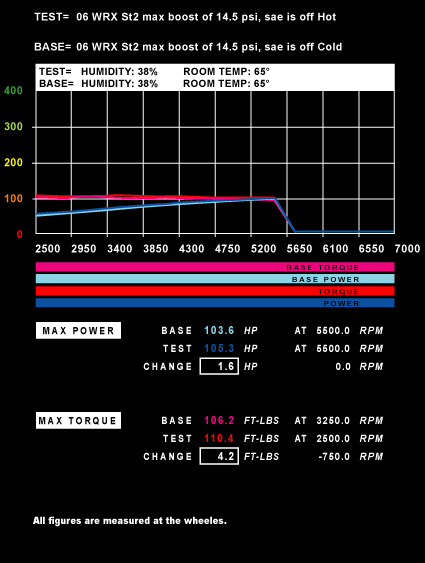

The most rewarding feeling when street driving a turbo charged car with a TMIC is response, hands down. When you can build 14-20 psi around 2800-3300 rpms then you have all the response you will ever want in a car. Enough power………well that is a different story. Street cars are usually in the 3500-5500 rpm power band on a daily basis, which is why TMICs work so well. However, heat soak is a major factor that contributes to loss of air density. Heat soak occurs in bumper-to-bumper traffic, stop lights or any other time the engine is at an idle. Sometimes the temperature outside is cold enough where there is minimal change in the IAT at the above conditions. However, just like the intake manifold, once the metal of the intercooler end tanks and piping absorbs the heat, it is hard to cool them down, therefore making it harder to raise the air density of the intake charge. Immediately below are some examples of turbocharged Subaru cars with TMICs.

RFMIC

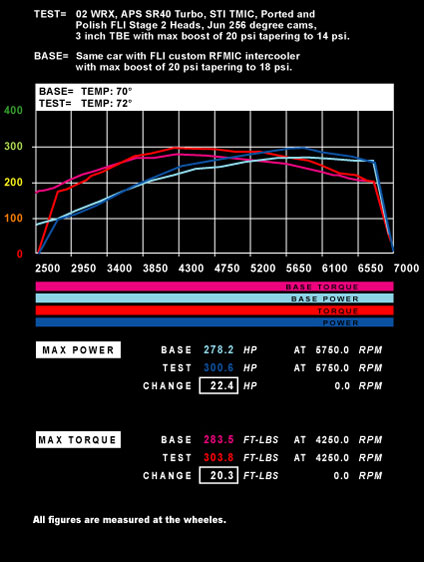

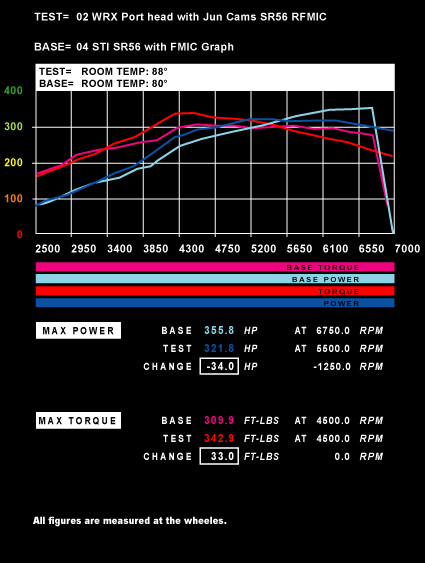

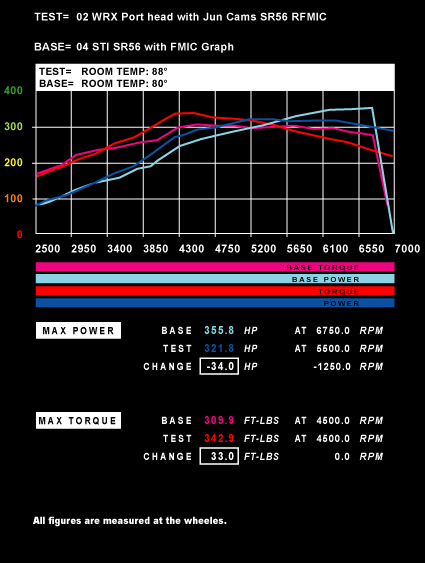

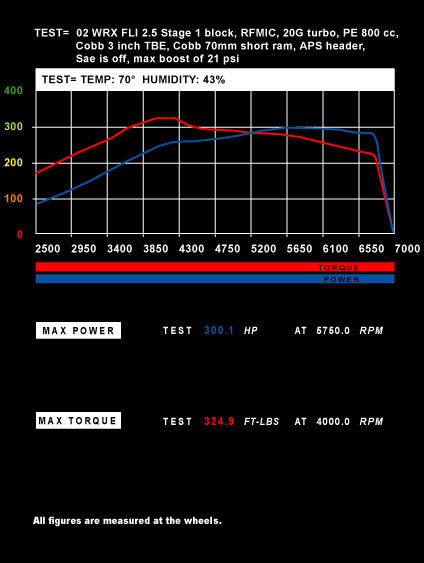

RFMIC stands for reverse intake manifold front mount intercooler. On a Subaru boxer style engine, you can simply flip the intake manifold 180 degrees and help eliminate 1-6 feet of piping depending on the intercooler kit. This modification will decrease lag and support more boost at higher rpms. Unfortunately, this is not as easy as it sounds. Like most custom car modifications, this modification requires time and money. You will typically pay about double for the customization of parts and labor to install the RFMIC when compared to the installation of a FMIC. However, with the RFMIC, you can create a happy medium between the FMIC and TMIC. For more information visit here: FLI RFMIC Examples-hyperlink. As you can see by these dyno sheets directly below, a RFMIC will make more boost (more power) at lower rpms. The first graph below is a non AVCS 2.5L 02 WRX with ported heads and upgraded camshafts compared to an STI with AVCS and a FMIC.

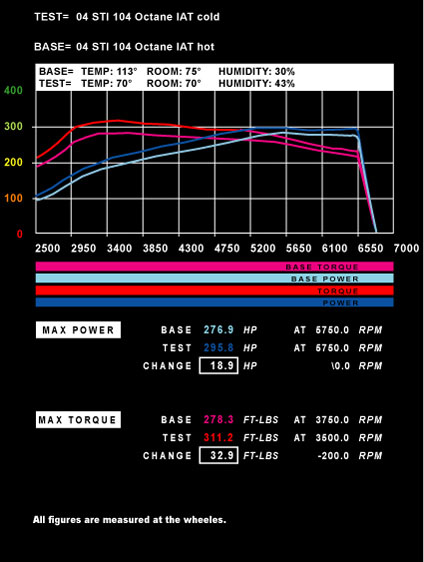

COLD vs. HOT Dyno Runs

The graphs below show many examples of hot vs. cold dyno runs back to back using the same cars, on the same day with the same gas and ECU map. Please read the description for IAT (taken by an external reading on the intake manifold) and temperature with humidity comparisons of the dyno room. As you can see, heat kills power.

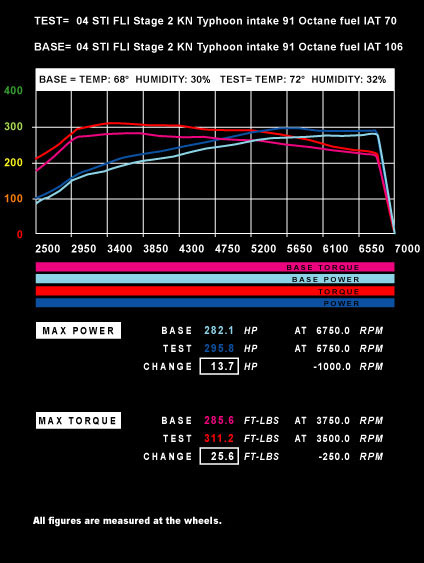

HIGH OCTANE RACE FUEL

It is no myth that the higher the octane level of your fuel, the more power you will get from your engine with the proper tune. However, you will pay between $7.50-$10 a gallon for 100-109 octane fuel. Here at FLI, we frequently map cars running on race fuel, ranging from customers who mix 101 octane with 91 octane to achieve a 95 or 96 octane rating to others who run straight 101 or 104 octane fuel. The reason you can get more power from higher octane fuel is is that higher octane fuel contains more carbon to carbon bonds than lower octane fuel. These carbon to carbon bonds contain more energy than carbon to hydrogen bonds, which are more common in lower octane fuels, and will release more energy when the bonds are broken during the combustion process. Hence a fuel with a greater number of carbon bonds will carry more energy. Keep in mind that you must have a well tuned engine that is operating at a respectable VE percentage. Here is an example of increasing power with running higher octane fuel.

Running race fuel does not mean that you will not be affected by heat soak. You can see in the following example that with the IAT increasing over 50 degrees, you still can have heat soak. Actually, this particular car made less power on 104 octane with high IATs then it did with low IATs and a 91 octane map!

Methanol/Water injection kits can solve the problem of heat soak and rising temperatures in the combustion chamber.

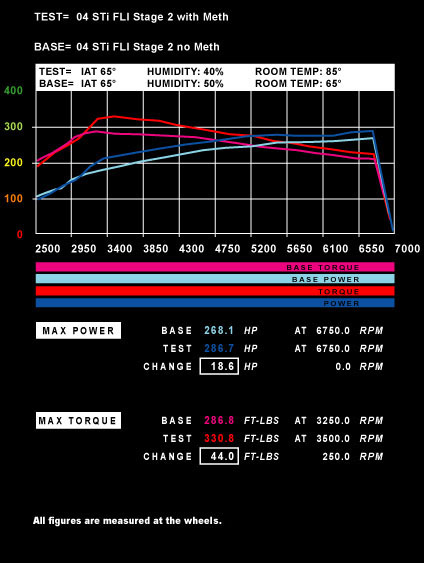

METHANOL/WATER INJECTION

You now know that one of the keys to making power is air density, but what happens when you live in an area with hot summers or warm weather year round? Heat soak is much more of a problem in warmer climates but you can still be effected by heat soak no matter where you live and intercooler water spray kits only do so much.

A good solution to the problem of heat soak is a Methanol/Water Injection kit. The purpose of this kit is to lower the intake air temperature and more importantly, lower combustion chamber temperatures. The mixture is usually 60% methanol and 40% water because water is much denser then methanol. FLI has done extensive research and development on the Aquamist HFS-5 kit. (hyperlink to the Aquamist HFS-5 on site) This kit uses a unique load measurement to activate and spray the methanol/water mixture. The HFS-5 kit uses fuel injector duty cycle (FIA unit) as the load rather than manifold air pressure or boost. This is a much more precise method of injection. The mixture sprays 1:1 with the injector duty cycle, creating a nice linear curve.

The HFS-5 kit also has a mechanical fail safe feature which switches the wastegate actuator to whatever the spring is set for on the turbo if a clog is detected in the line or if you run low on the methanol/water mixture. For example if you have a factory U.S. STI turbocharger, the actuator has a spring pressure of around 13.5 psi. If your custom map has boost targets of 20 psi tapering to 14 psi and the system detects a clog or you run low on fluid, the maximum pressure allowed will be 13.5 psi. This feature can save an engine!

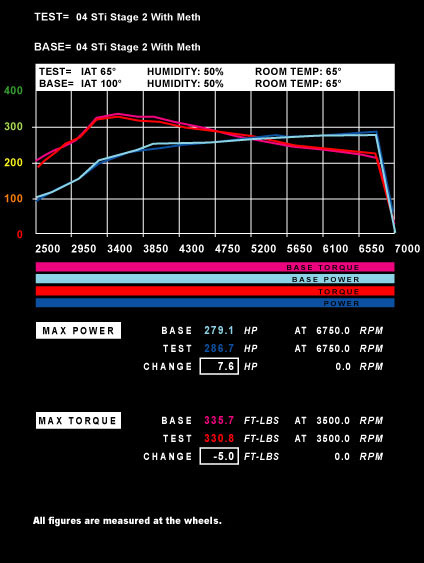

Now here is where the power of air density gets interesting. The methanol/water nozzle is usually mounted somewhere near the throttle body, which allows it to spray in the intake manifold. FLI performed a test with the HFS-5 kit on a 2004 STI that has a custom FLI Stage 2 map, catted turbo back exhaust, factory turbo and intercooler kit. The cold run temperatures were: Dyno room = , Dyno room humidity = , IAT (intake air temperature) = 66 degrees. In these conditions this STI made 335 wheel torque and 279 wheel horsepower. The hot run temperatures were: Dyno room = , Dyno room humidity = , IAT = 101 degrees. In these conditions this STI made virtually the same power as you can see from the graph below. This means in the summer time, on a race track or any other time when the heat is high, a methanol/water injector kit can actually help a car make almost the same power as it would in the winter!

CONCLUSION

To make good power, you must start off with a well tuned, well maintained engine running good fuel (good quality 91 octane at a minimum). The engine must also have all the mechanical upgrades to support the movement and volume of air/fuel mixture to make power. You must also think about the power band you want for your vechile. Making big power does not always mean your car will run better. There are many other factors when making power that are not mentioned in this article. However, air density is one of the most overlooked factors when comparing dyno sheets, turbochargers/exhaust combinations, compression ratio, engine size and cams or head packages. Next time you read a dyno sheet from one of your friends, ask them if they know what the temperature and humidity was in the dyno room at the time of their dyno run for a better baseline of comparison.