Where the factory ECU ends and Link begins

Where the factory ECU ends and Link begins

Technology has revolutionized today's world in many ways. Auto manufacturers are using this technology in their cars' electronic control units (ECU), which functions as the brain of the car. These new powerful ECU's have many built in features for monitoring, adjusting and controlling fuel, spark and air at a rapid rate. This helps a car adjust to sudden or gradual changes in humidity, barometric pressure, ambient air temperature, throttle position, driving style or fuel quality. Think of an engine as a big air pump. The amount of air/fuel mixture (or charge) you can move in and out of an engine is called Volumetric Efficiency (VE). Since an engine's VE is a static number (the maximum air/fuel charge an engine can produce), the goal is to try to achieve that maximum air/fuel charge, which will in turn produce more power. This is where powerful ECU's come into play. These brains have the ability to control and adjust fuel, spark and air (if equipped with a turbo) at a very fast rate. How do you know which package makes the most power in the power band you want? Experience. However, even with experience, each shop will have their own opinions about what will work best for your car. Even with all the technology provided in modern ECU's, there are limitations to these factory units. Let's use the 2002-2005 Subaru WRX as an example. These cars come with a turbocharged 2.0 liter engine boosting around 14.5 psi in stock trim. To monitor the mass of air entering the engine, Subaru uses a Mass Air Flow sensor or MAF. The MAF measures air in grams per minute or pounds per hour. From this measurement, combined with the barometric sensor (BAP), manifold air pressure or MAP, and intake air temperature sensor (IAT) information, the ECU knows how dense the air is at any particular time. In this article, I will be mainly comparing the factory USA Spec 2005 Subaru WRX MT ECU to a Link G4 stand alone ECU. I have the most experience with Link ECUs', but FLI also specializes in Cosworth's ECPro (Pectel) and Hydra EMS stand alone units.

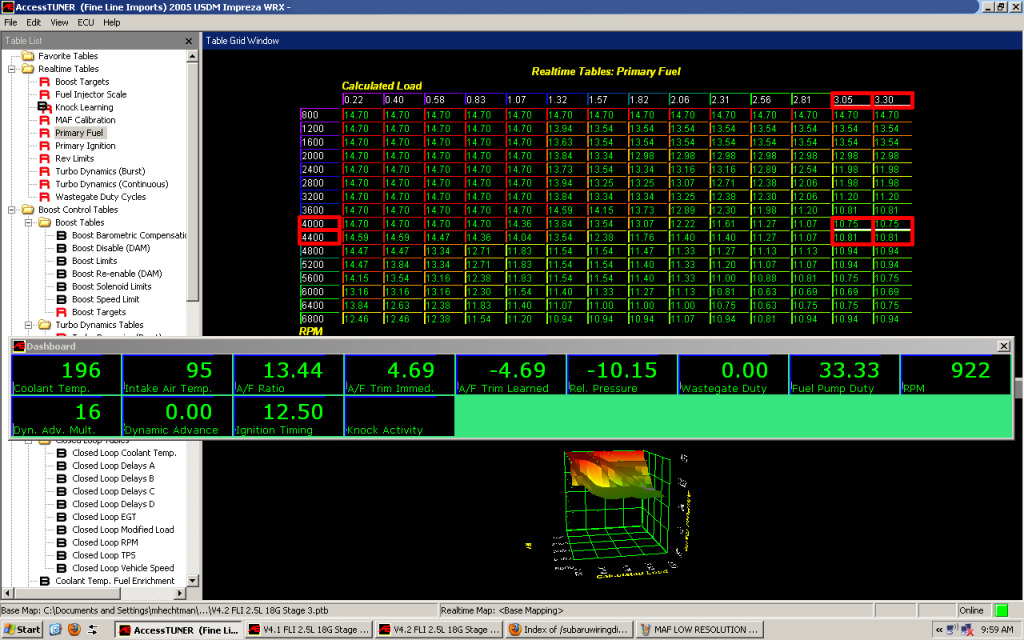

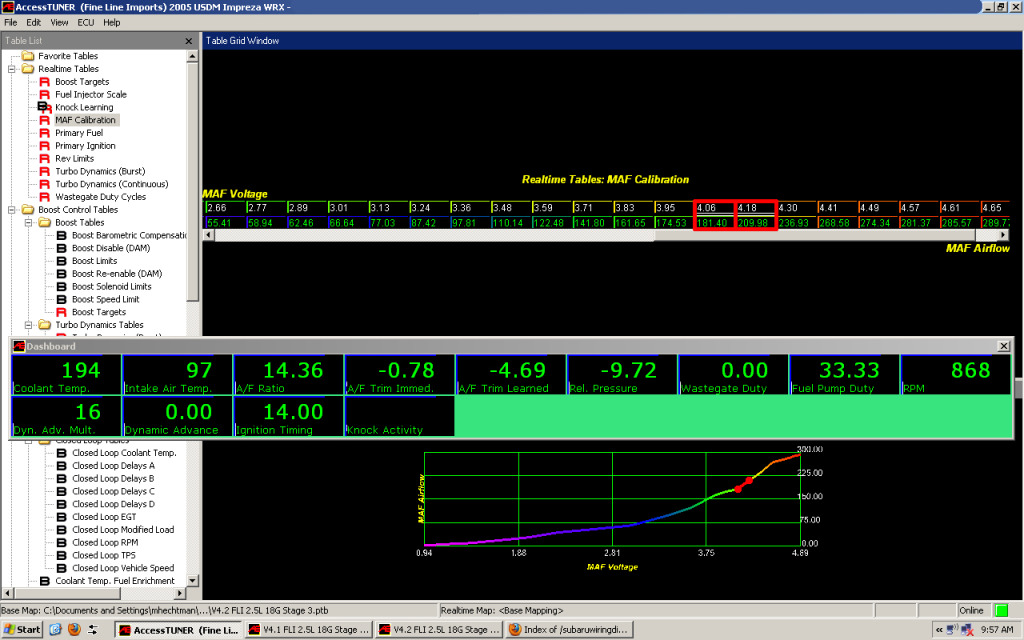

FUEL Here is a brief description of how the fuel system works in a 2002 - up Subaru turbo charged ECU. There are two main ECU controlling functions, closed loop and open loop. Closed loop means that the ECU gets feedback from the engine sensors which allows the ECU to make adjustments to hit your fuel targets in the main fuel table. The ECU only can only adjust + or - 25% during closed loop control. Open loop means the ECU does not make any adjustments and what ever comes out of the tailpipe is derived from the data in the main fuel table and MAF calibration table. Open loop occurs roughly 20-30% of throttle / load. You have a main fuel map, which is a 3D map where X is load (calculated) and Y is RPM. The way you hit the targets in the main fuel map is through the MAF (0-5 volt reference) table. This is a 2D graph where X is load (calculated) and Y is MAF voltage (0-5 volt). For example, let's say that you want to achieve a air / fuel ratio target of 14.7:1 with partial throttle at 3500 RPM. The ECU looks at that giving load site in the main fuel table combined with load site in the MAF table (voltage). If the air / fuel ratio is off from your target, then you would need to adjust those load sites in the main fuel table and MAF calibration table. In openloop, the ECU still looks at the specific load sites but does not make any adjustments. So, whatever comes out of the tailpipe is directly related to the data in those windows. You might be saying to yourself, okay, so where's the problem?

With minor modifications to the vehicle such as a slightly bigger turbo, intercooler and fuel injectors, the ECU (if mapped correctly) should have no problem controlling and monitoring all these upgrades on its own. However, on more complicated builds with larger heads, camshafts, fuel systems or larger upgraded engines there will be a limitation of the factory ECU’s parameters. For example, if you upgrade the stock 2005 Subaru WRX 2.0 liter engine to a 2.5 liter engine and use the factory 2.0 liter ECU, there is a chance you will run into a resolution problem. One major factor is the MAF housing size. On FLI’s dyno, anything over 300 torque to the wheels on a 2002-2005 WRX must have 70mm or larger MAF housing size. Anything over 340 torque to the wheels must have 80mm or larger. This may not seem like a big deal. Just increase the diameter of the MAF housing so you can correctly map the fuel table, right? Well not exactly. When you increase the diameter of the MAF housing, ! you gain a few windows at top but you lose resolution (in the MAF table). This causes less room for fine tuning. Not only that, but the 2002-2005 WRX ECU only reads a maximum of 300 grams of air per minute or pounds per hour. In late model 2.5 liter WRX’s, XT’s, turbo charged Legacy’s and all STI’s the maximum the ECU can read is 500 grams of air per minute which is 40% more then the 2002-2005 WRX ECU. With the later model ECU’s, there is more resolution to work with but you still can run out. To explain this low resolution in detail, I have taken a couple screen shots of a factory 2005 Subaru WRX MT ECU fitted with a 2.5 liter shortblock, 18G turbo, TMIC, PE 800cc injectors, catted turbo back exhaust, Tomei Equal length header / up pipe and Cobb 70mm short ram intake. This application is a great example of maximizing the factory ECU parameters and running out of resolution to tune fuel.

You have the main fuel map (3D, RPM crossed with calculated load) and the MAF calibration windows (2D window, load site is MAF voltage 0-5 volts crossed with MAF Air flow). The ECU looks at the main fuel map and tries to hit the targets in those windows (in closed loop only - ECU can control + or - 25%). Otherwise, under full throttle (or open loop - ECU does not adjusts) what comes out of the tail pipe. This is based on numbers in the MAF table (under that specific load, i.e. MAF voltage and MAF Airflow) and the main fuel map numbers (under that specific load, i.e. RPM and calculated load). Basically, the ECU looks at these two parameters for the majority of the fuel control. There are lots of other windows for injectors, partial throttle, open / closed loop, etc. but I am trying to keep it simple and talk about wide open throttle tuning here. So where is the low resolution problematic? Let's say you want to take out 4% of fuel at 4200 RPM with full throttle, which is a calculated load site of 3.25 and a MAF Voltage of 4.12. Under the main fuel map, the allocated windows are 4000 RPM and 4400 RPM. Under the MAF calibration parameter, the allocated windows are 4.06 and 4.18. This is where you run out of resolution in the factory ECU and you have you split the differences between the load sites and start to use numbers that really do not make sense in the essence of how Subaru created this ECU to control fuel. I am not saying you cannot get a good tune from this, but what I am saying is that the tuner is limited by the hard code written software that Subaru designed which can be very frustrating and cause issues which cannot be tuned out.

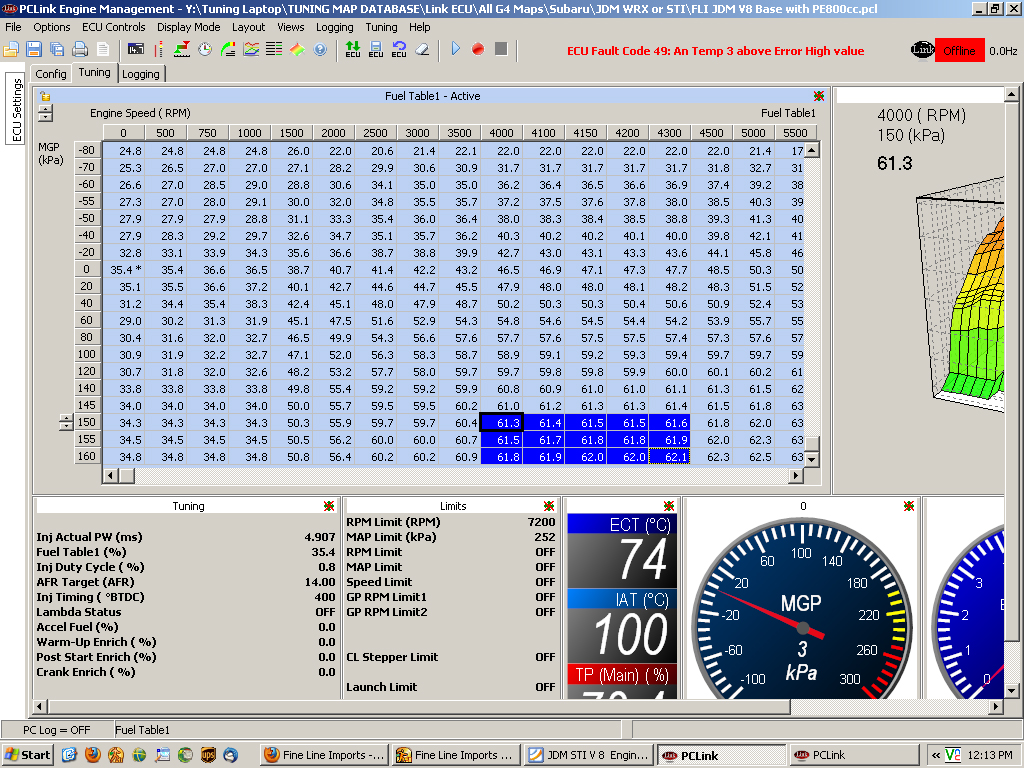

This is when FLI recommends using a stand alone ECU, where you can create new columns or rows if need be for more resolution (Link G4 ECU's). Here are some screen shots from a 2005 Subaru WRX MT Link G4 ECU. I will use the same example between 4000-4400 RPM with wide open throttle. In the Link G4 ECU, there are many options to maximize resolution in fuel, timing and boost parameters. I will only be talking about fuel now. In the main fuel map you can add up to 22 columns and 20 rows. I have added four columns and 3 rows which allowed for 15 total windows between 4000-4400 RPM. This is compared to only 6 windows in the factory ECU. Let's say, you still need more resolution.

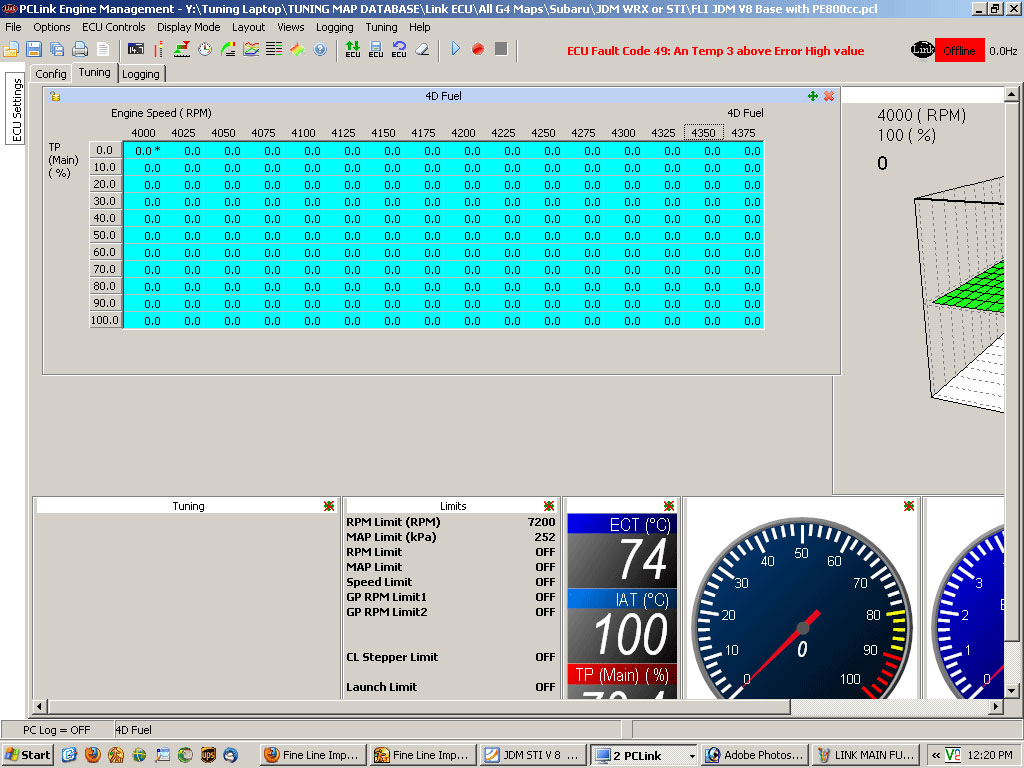

The next layers of resolution that Link ECU offers are called 4D (dimensional) and 5D windows. The 4D is an overlay window of the main fuel map. This 3D window allows you to set the starting and ending points (of both X and Y Axis) along with the load you want to use (RPM, Gear, Coolant temp, Throttle position, or any of the digital inputs / outputs, etc.). For example, if you wanted to remove 4% fuel between 4000-4400 RPM and for some reason you ran out of resolution of the main fuel map, then you can create a new 3D overlay map (4D) and start the RPM load site with 4000 and end with 4400. This allows more then 100 new windows with the adjustability of changing the load used. Here is a screen shot of this.

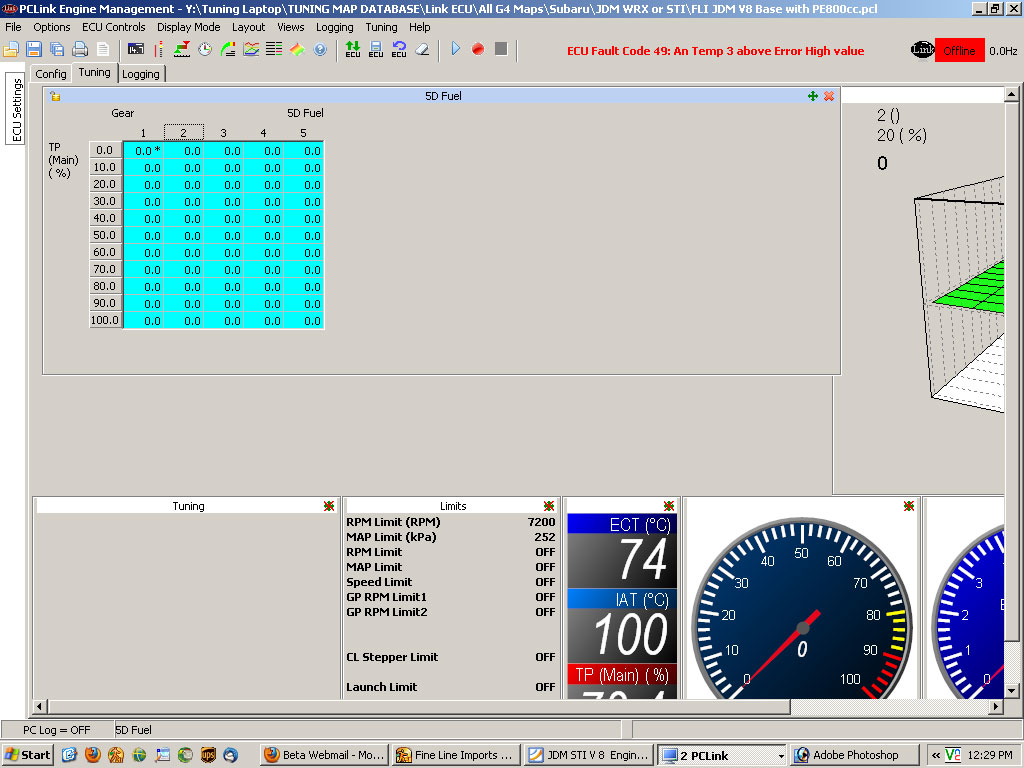

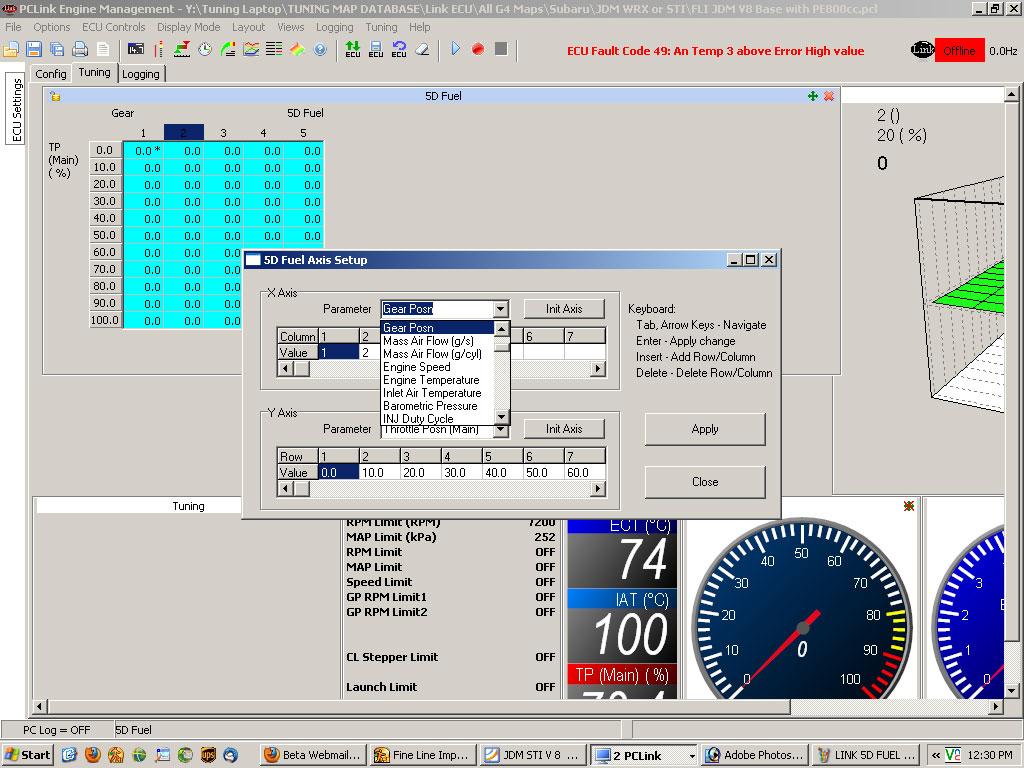

This should solve any fuel resolution needed for this particular 4000-4400 RPM issue. However, lets say it does not. For example, this fueling issue only happens in 4th gear with 65% throttle. Now hear is where you can use the 5D fuel option. This allows you to set the load site to each gear (5 in a 2005 WRX MT car) crossed with throttle position to fine tune and solve this issue. Here are some screen shots of these examples:

MAP SENSOR Another limitation of any 2002-2007 Subaru turbocharged stock set up is that the factory MAP sensor only reads up to 22.42 psi. This means if you want to run 24 psi and have fuel cut (a built in safety system which cuts fuel 100% at a given target) then you would need to install another MAP sensor that can read higher pressure (for example, Zeitroix or AEM 3.5 bar with a Cobb Tuning sensor adapter). Link has a 2.5 bar or 5 bar optional map sensor which can be used with any Link G4 ECU.

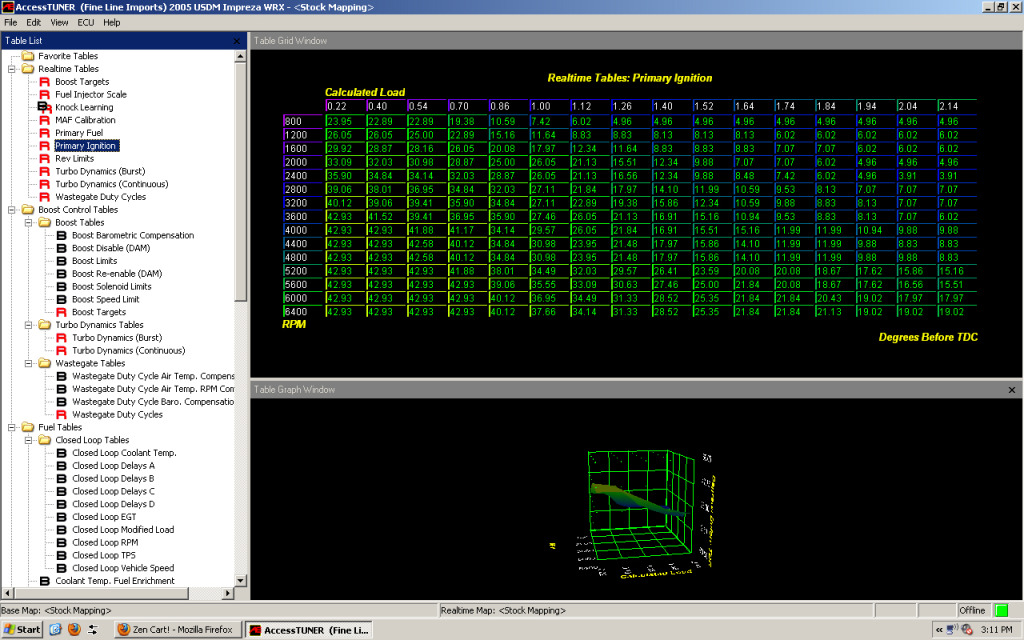

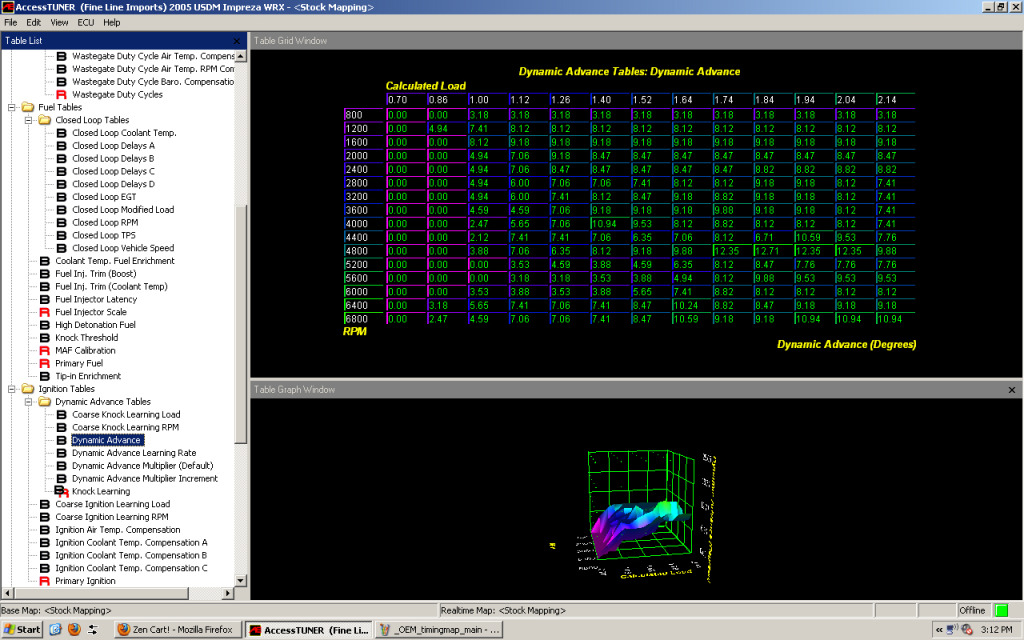

TIMING / KNOCK CONTROL Timing is a very basic control for the most part. However, the factory 2002-up Subaru ECU actually controls timing in the same way it controls fuel with the exception of only having the closed loop option. There is a main ignition 3D map where X is calculated load and Y is RPM. This is where you set your ignition targets. The ECU has 3 or more windows called Dynamic Advance. This is where you can set the ceiling for how much timing the ECU can add on top of the main ignition map. If the ECU detects knock or detonation, then the ECU will subtract timing if the target is too high in the main ignition map. Obviously poor fuel quality and hotter intake air temperatures will increase the chance of knock or detonation. The factory Subaru turbocharged ECU controls timing and knock pretty well. When you have large camshafts, head work, larger throttle bodies, forged pistons, etc., you might run into some minor issues but still can be controlled in the factory ECU with minimal problems. However, the Link knock control system is much more dynamic. For example, you can control the sensitivity, when it starts, when it ends, add additional knock sensors and really fine tune the knock system in general. There is also an optional Link Knock Block which is a stand alone circuit board (can be used with head phones as a shop tuning tool) that is very sensitive and can be adjusted manually. The knock block is also recognized by the Link ECU for datalogging, feed back, monitoring, etc. Not only that but you can have individual cylinder knock trims where as the factory ECU cannot. Each of the tables load sites can be changed, along with the columns and rows for more or less resolution. As you can see in the factory ECU, on the left (in pictures, under Ignition Tables), there are a few other Dynamic Advance windows that can be adjusted as well. Here are some screen shots of the factory Knock Control system (Dynamic Advance and Main Ignition windows:

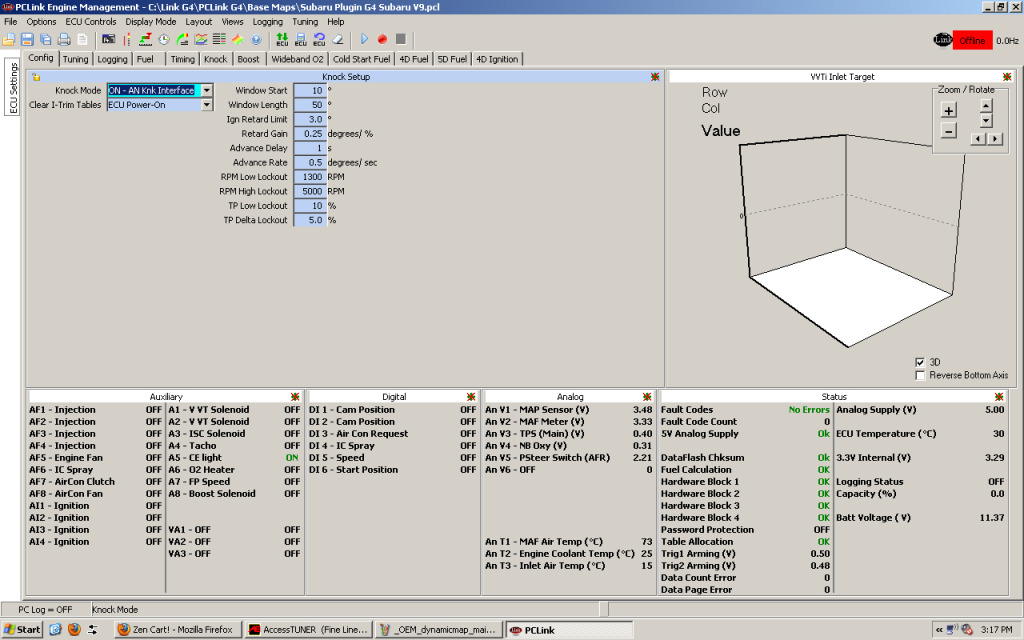

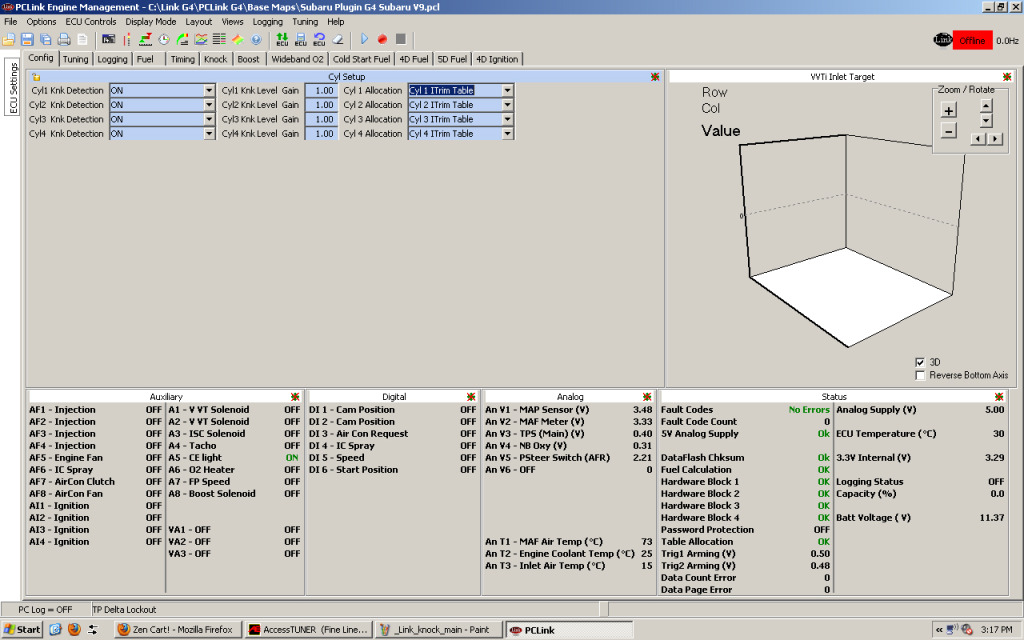

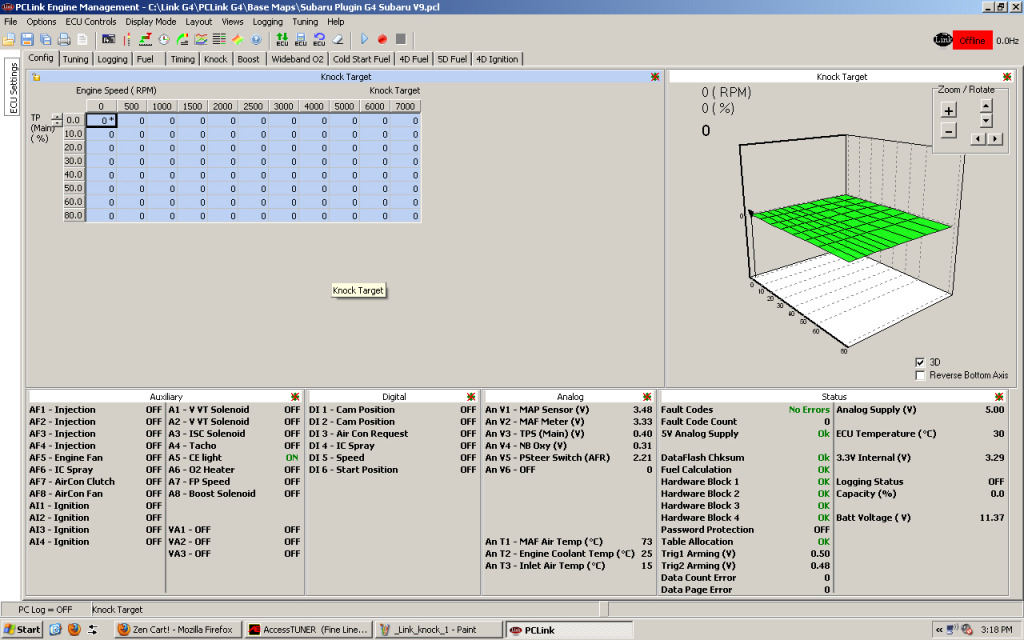

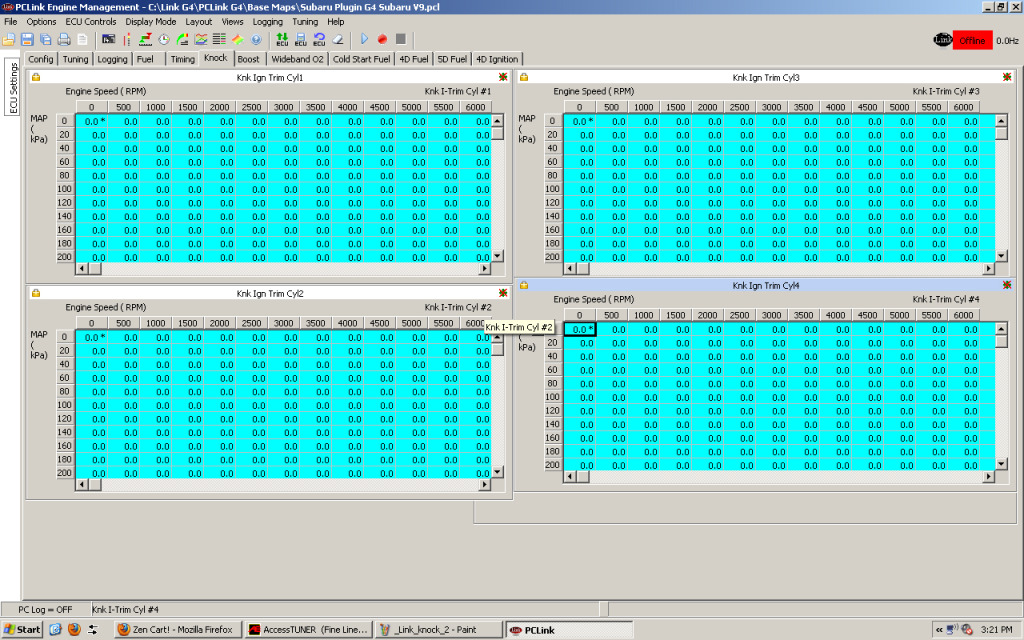

To give you a visual idea of the control that the Link G4 offers, here are some screen shots of the knock control system:

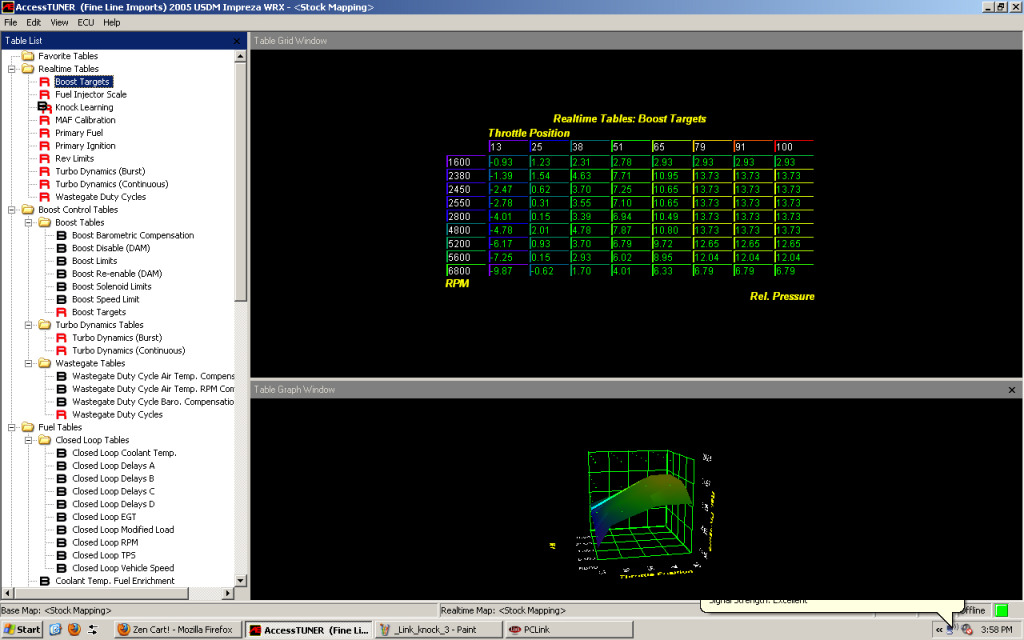

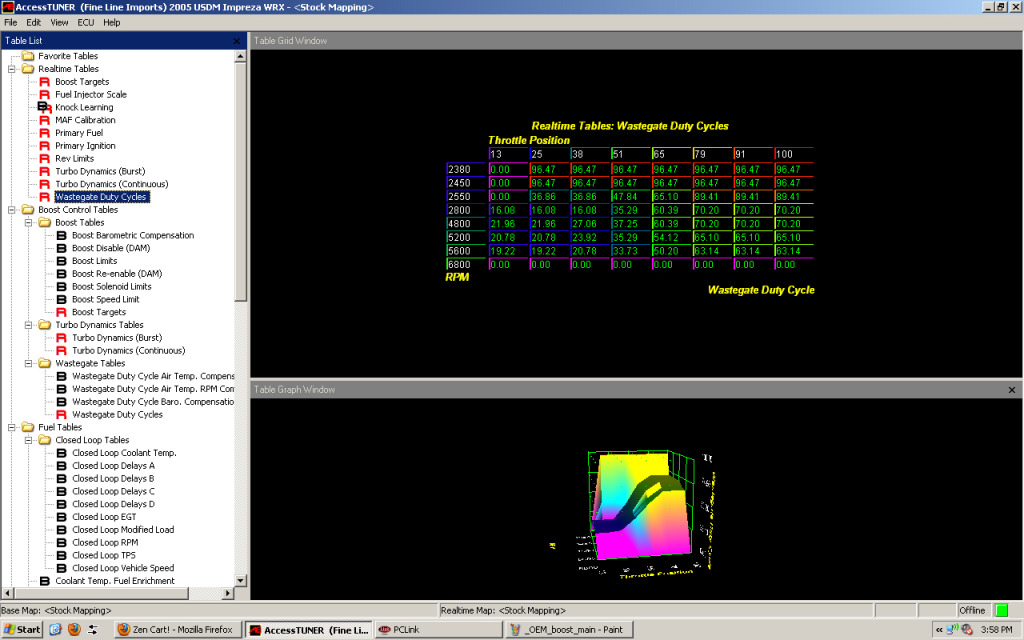

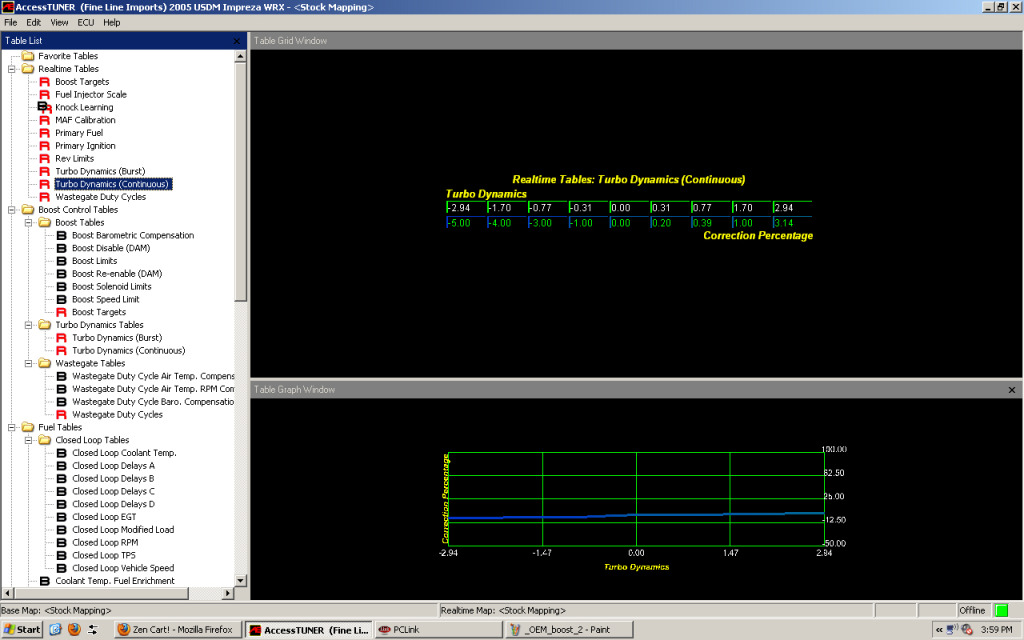

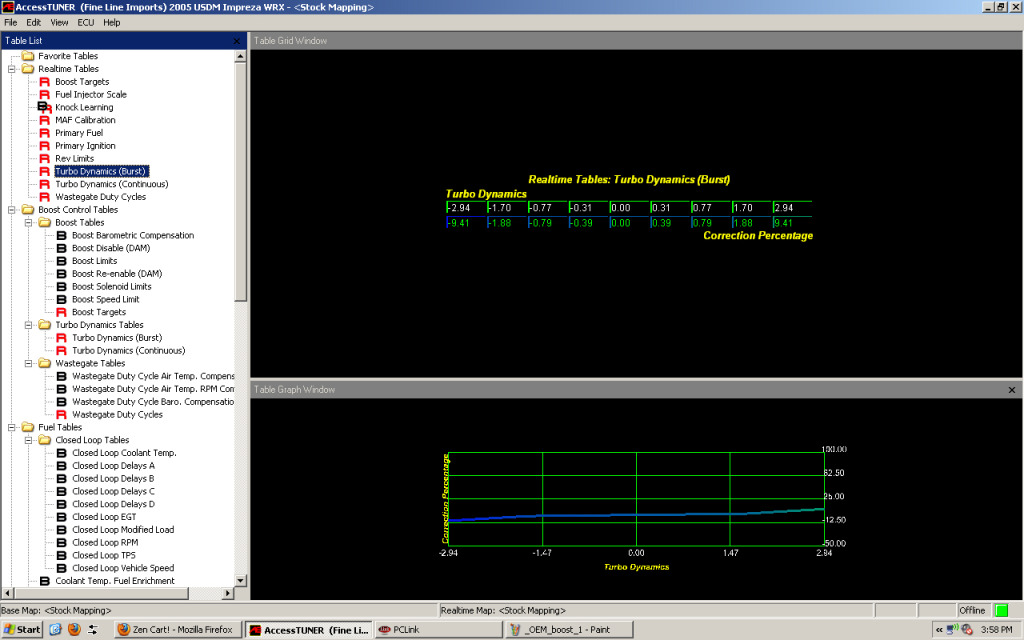

BOOST Boost control is one of the most important mapping features when tuning a car. This is because different levels of boost cause different load sites to be active, thus affecting timing and fuel. The factory (2002-2010) Subaru ECU uses a closed loop boost control system, which also has a main 3D boost map (X is calculated load, Y is RPM). This works the same as fuel and timing; it is used for setting boost targets. To hit your boost targets there is one wastegate duty cycle (WGDC) map in the 2002-2005 WRX ECU and high and low WGDC maps on all other turbo charged Subaru ECU's. The WGDC map controls the wastegate solenoid, which controls the turbo's wastegate actuator. There are 3 other windows in these ECU's, which provide some control for over-shooting or under-shooting your boost targets. For the most part the boost control system works very well up to a certain point. Here are some screen shots of the factory boost control parameters:

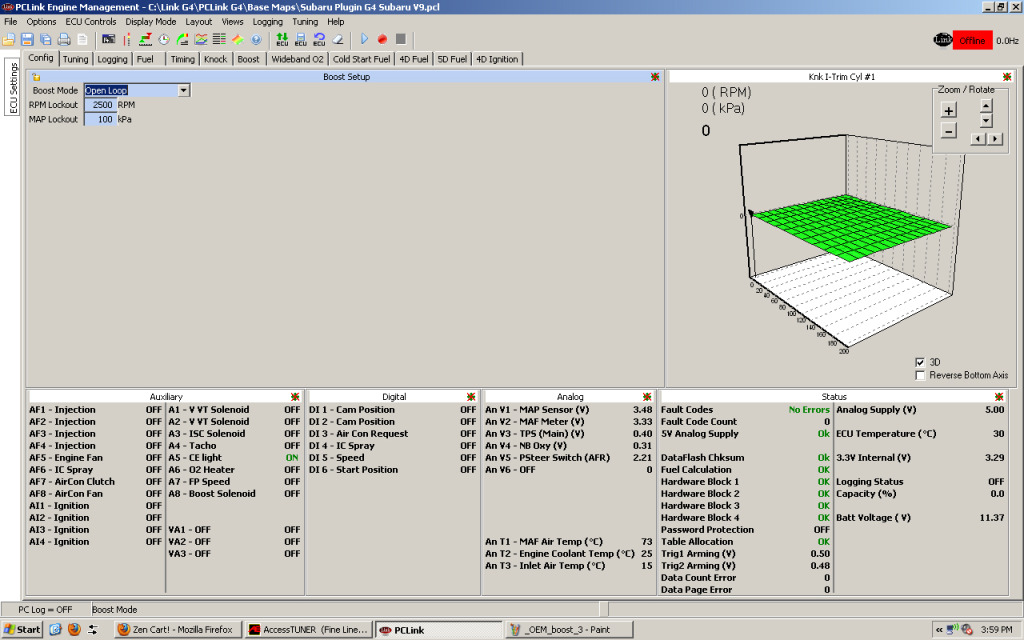

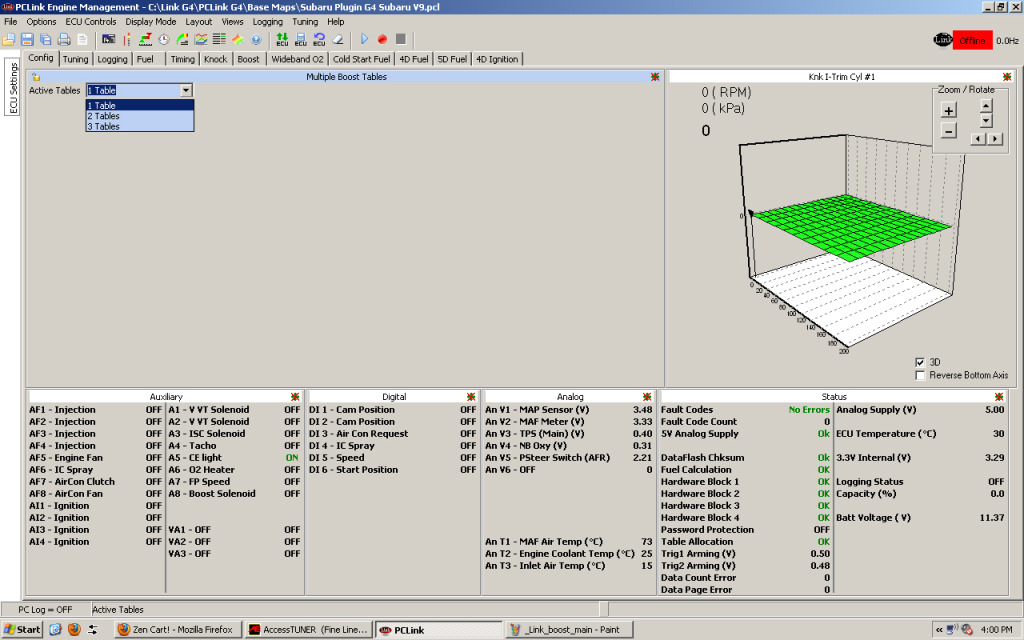

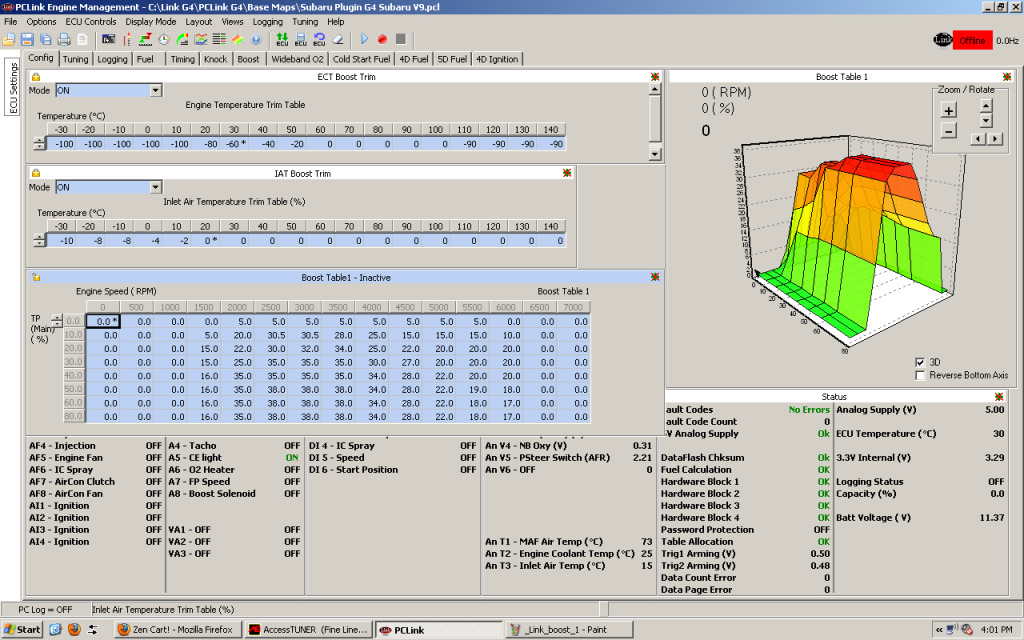

The Link G4 boost control system works only in open loop (right now). Key features are, gear dependent boost control (each gear has a different map, minimal boost is wastegate spring), up to 3 different boost maps on an external or internal switch (digital outputs) and trims for intake air temperature and coolant temperature. The Link boost control is a very good system. Here are some screen shots of the Link G4 boost control:

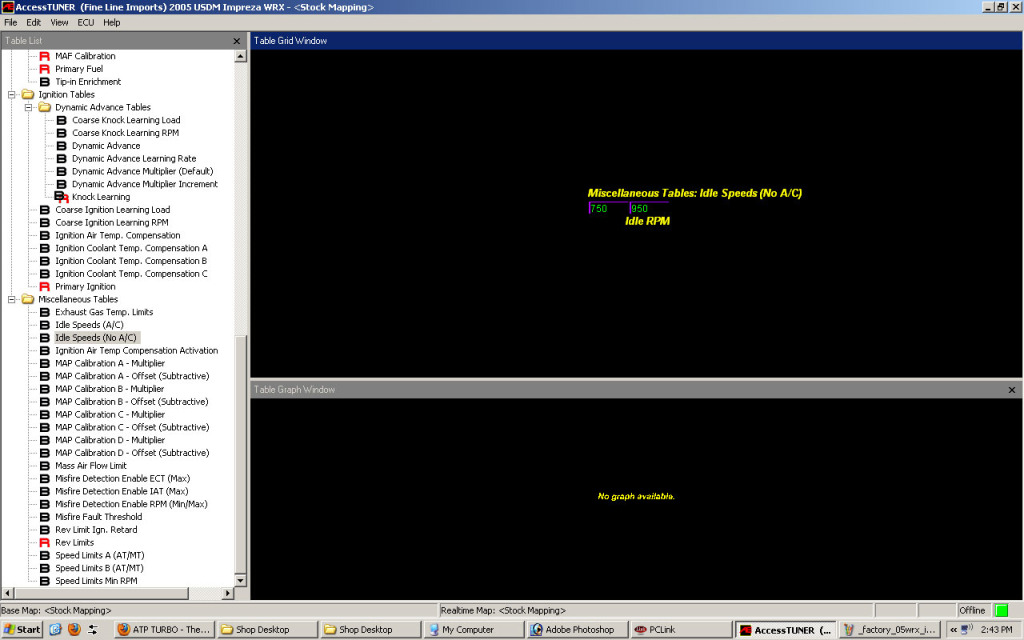

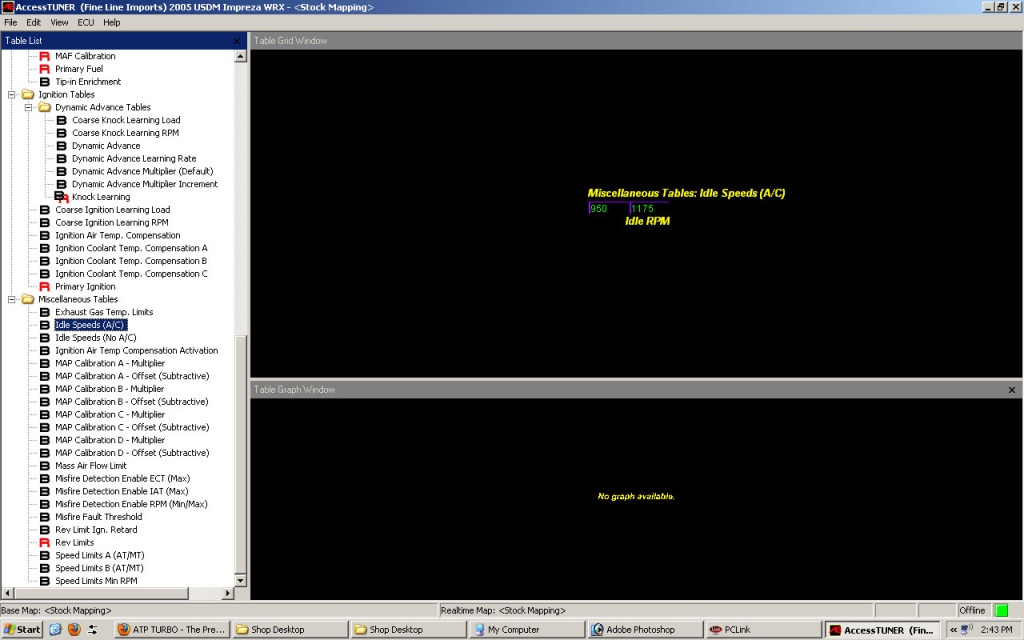

IDLE Another parameter in the factory ECU that has no resolution is idle. There are basically four windows to work with. Idle with and without the air conditioning fan on. All idle windows are closed loop and the tuner does not have good control over idle. All fueling is done by the MAF calibration 2D window. Here are some screen shots of the 2005 Subaru WRX factory idle windows:

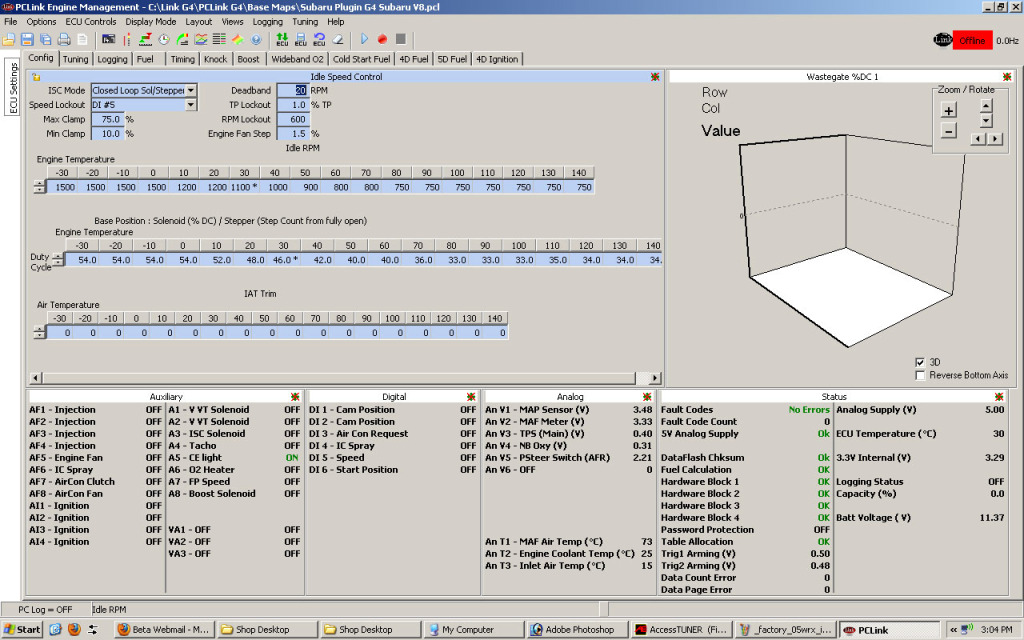

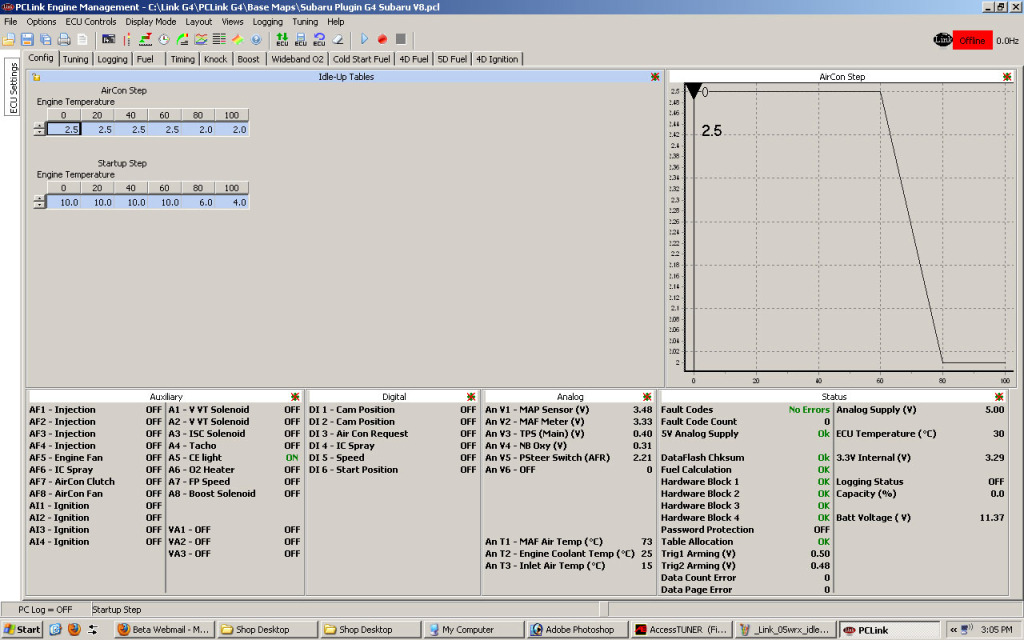

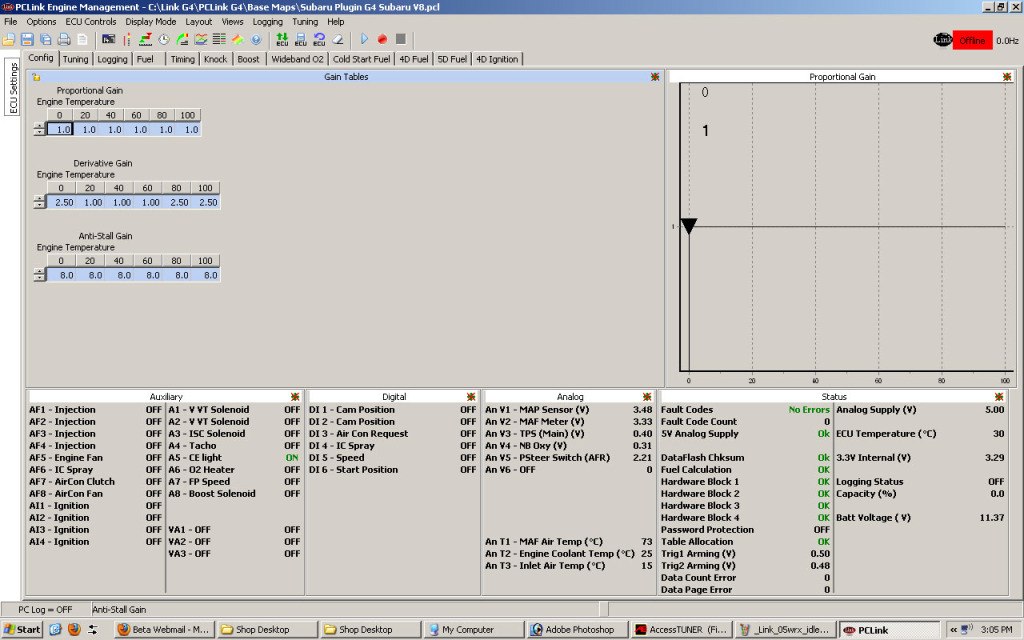

Link offer's 16 different idle windows that use coolant temperature, clamps, PID control, idle gains and idle speed solenoid open loop control. Personally, I have had 1200cc fuel injectors on a fully built STI (ported heads, large camshafts, etc..) idle at 900 RPM with no issues and great idle control coming down from RPM's! Here are some screen shots of these:

STAND ALONE ECU'S FLI supports three different Stand Alone ECU's for Subaru's, EVO's and 350Z/G35: Link ECU, Cosworth's ECPro and Hydra EMS. The Link G4 Stand Alone ECU offers an open loop boost control system (gear dependent) and sophisticated fuel, timing and idle windows (open loop, but also can be put into closed loop after you create a good map). Gear dependent boost control means, you can map boost for each gear. Each gear has a 2D map that controls WGDC. This is the ultimate control for boost because each gear has different load sites. The Link G4 ECU is capable of reading up to 65 psi of boost (optional 5 bar map sensor). This is a superior way to control and create a stand alone ECU map. Link offer's many plug in ECU applications including Subaru WRX / STI V1-9, Nissan S13-S15, Nissan R32-R34, Mitsubishi EVO 1-9 and some Toyota models. Cosworth's ECPro offers military grade quality and very well written software. They also offer a fantastic stand alone datalogging system which was used by Formula Ford Europe until 2006. This platform is based on the factory ECU using a MAF sensor. However, the detailed parameters that are available allow the tuner to not be limited when tuning. Closed loop fuel, timing and boost control is standard in the ECPro. At this time, they offer two plug in models (08-up STI and EVO X). The Hydra 2.5/2.6 stand alone ECU operates a bit differently. The Hydra also allows you to control boost for each gear. However, it uses a closed loop control system (PID - proportional–integral–derivative), much like the factory Subaru ECU, instead of an open loop system. You have a main boost map, like the factory ECU, with 2-4 windows to control over or under shooting your boost targets. You cannot map each gear with a separate 2D WGDC map but you can add or subtract a percentage from the overall boost map using a single digit value for each gear. The Hydra 2.5 unit only provides access to 4 gears (was developed for traction control initially). Both systems work very well. The Hydra 2.5 or 2.6 both control up to 30-35 psi of boost with no problems. The fuel, timing and idle controls in the Hydra are always in closed loop as well. You tune for correction like the factory Subaru turbocharged ECU instead of an open loop system like the Link G3/G4 ECU.

CONCLUSION Overall, it is ultimately up to your tuner and the software they are most comfortable using when tuning your car. It is important to realize that when your tuner is creating a stand alone ECU map, they are re-creating what the team of manufacturing tuners created over months and months of full time work. It is not an easy task, but definitely attainable and well worth the money. Trust your tuner and do not be afraid to ask any questions regarding your best friend, your beloved automobile. All information was written by Miles Hechtman, lead tuner of Fine Line Imports